Further Details

The biofilters are tank-shaped structures which can be manufactured using:

- concrete containment walls;

- aerated floor consisting of:

- round piping for aeration of the biotunnel;

- PVC components for the end connection of the piping to discharge the leachate consisting of: T connection and caps, screw caps for cleaning the transverse line;

- C-profile galvanised sheet metal to protect the spigots when casting the concrete floor (not supplied);

- anchoring collars and dowels, galvanised channels, polystyrene and screws, ties and any other components necessary for the correct assembly.

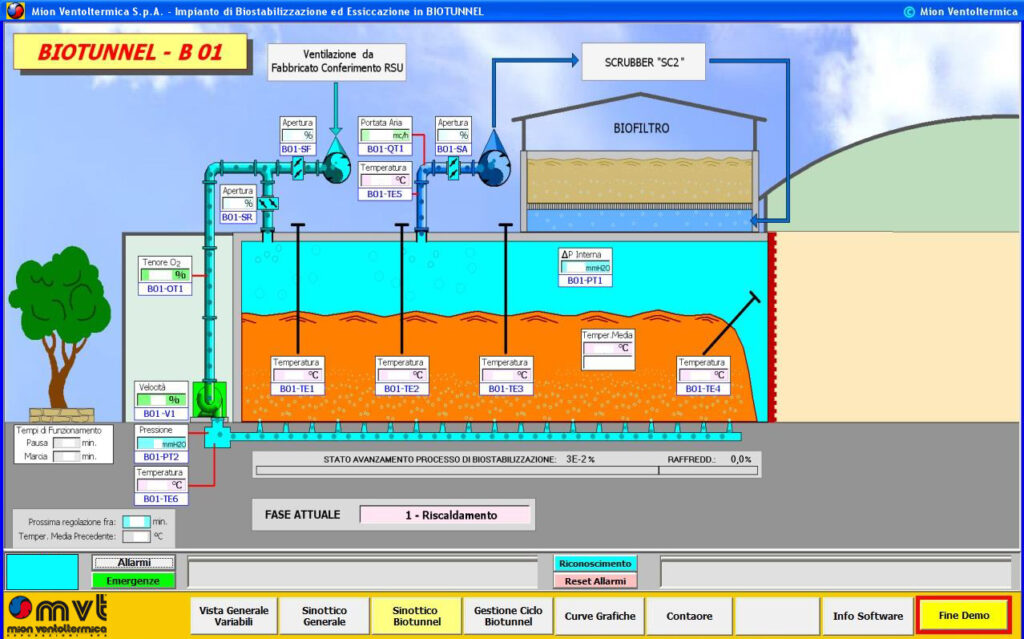

The biofilter is then equipped with a system of irrigation for the correct humidification of the material (biomass) and suitable instrumentation for measuring the humidity and temperature.

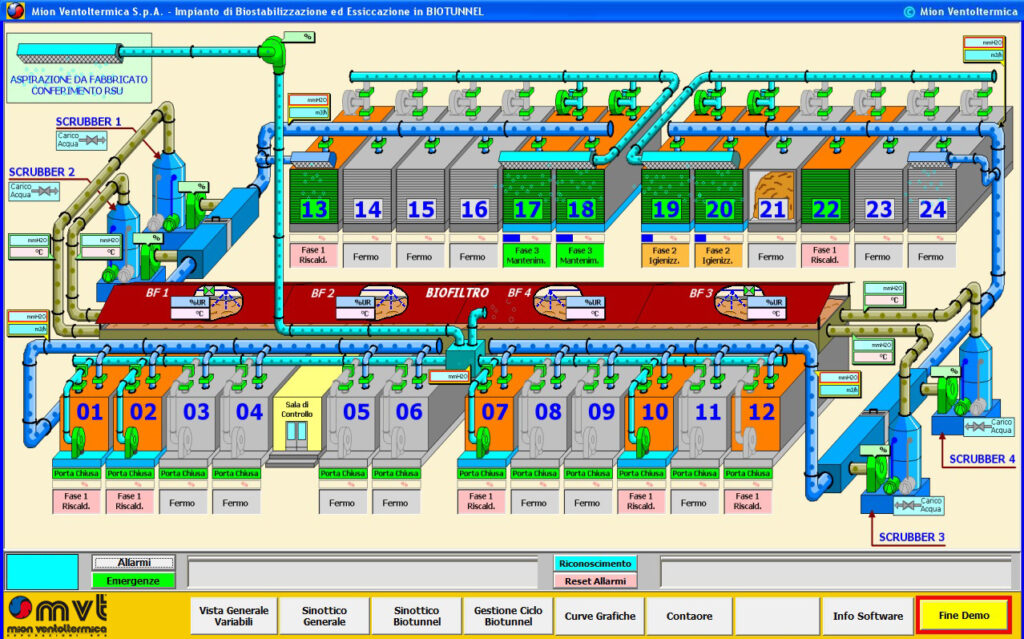

The complexity, as well as the myriad issues to be evaluated simultaneously to ensure the correct execution of the biofiltration process, requires the use of IT systems and software which we have specially designed and developed, so that the entire system can be monitored constantly and in real time.

ADVANTAGES:

- removal and decomposition of gaseous contaminants using micro-organisms;

- pavement which can be transited by trucks for the operations of placement and removal of the material;

- durability and solidity;

- a healthier and safer workplace environment.