Further details on this system

Systems for the production of Refuse Derived Fuel (RDF) are based on the use of Municipal Solid Waste (MSW), which is placed inside a biocell for bio-oxidation and drying.

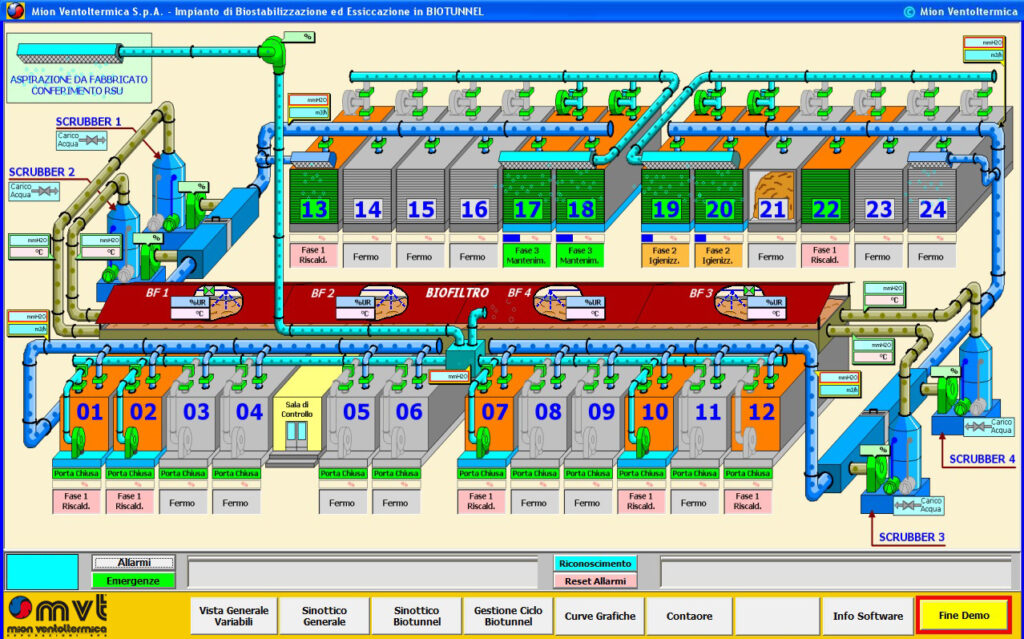

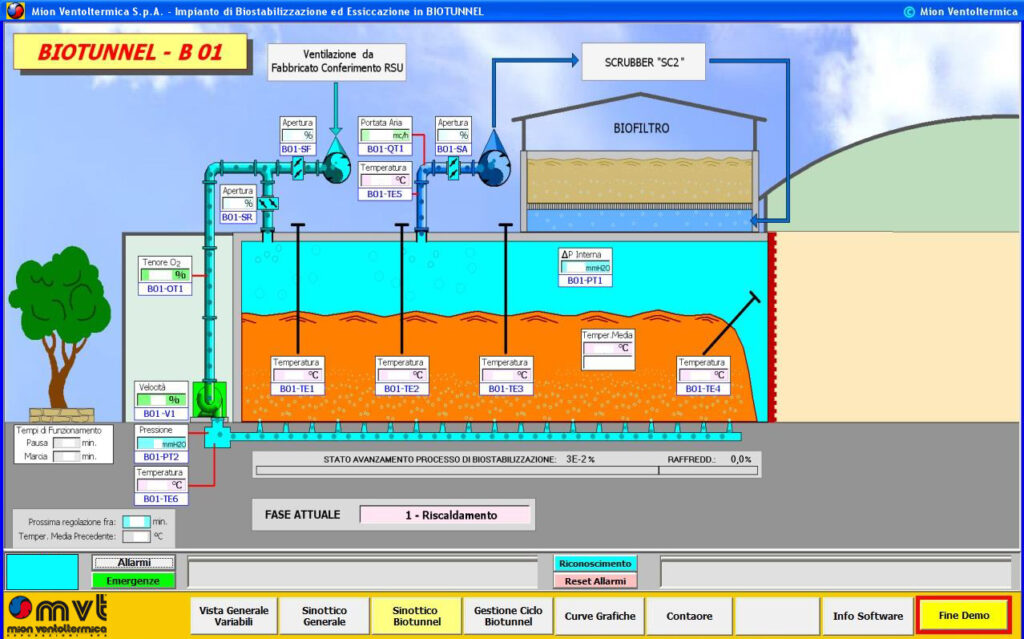

A biocell consists of a closed, impermeable construction made of reinforced concrete and provided with an aerated (or inflated) floor, within which there are a series of process parameter detectors that regulate the amount of air that is blown in from the aerated floor in order to maintain the refuse in the best conditions of temperature, humidity and oxygen concentration.

The dried product can be treated by the user in order to separate off certain materials that it consists of. After this, it is crushed and processed to obtain the RDF. The latter can be left in bulk, or stored in ecobales for greater convenience.

The unpleasant-smelling air produced throughout the entire process is sent through collectors and fans to scrubbers, which, in turn, moisten it and send it to a biofilter. The last stage of treatment of the gaseous flow takes place in the biofilter which then sends air with reduced concentrations of odorous substances into the atmosphere.

The number and complex nature of the issues to be considered simultaneously for the smooth running of the process require the use of IT systems and software, specially designed and developed by us, so that the entire system can be monitored constantly and in real time.

Due to our high production flexibility and know-how gained over the years, we can find the solution best suited to the needs of our customers and guide them in all decision-making stages.

REFUSE DERIVED FUEL PRODUCTION SYSTEM: BENEFITS

- reduction in the volume of stabilised mass;

- according to the characteristics of the incoming material, reduction of up to 50% in the weight of the feed material;

- production of high-quality RDF with high heating and combustion power;

- use in systems for the production of electricity if the RDF is burned in incinerators;

- recovery of non-recyclable materials that would otherwise be accumulated in landfill sites;

- waste disposal of only the fractions of waste that cannot be recovered in energy terms or as materials;

- healthy working environment though appropriate changes of air;

- reduction in the level of smells in the saturated air after treatment.